Współpraca z renomowanym dostawcą jest kluczowa dla wyboru odpowiedniej linii do cięcia na wymiar o średniej grubości. Kontaktując się z producentem, możesz uzyskać profesjonalne doradztwo i rozwiązania dostosowane do Twoich specyficznych potrzeb.Jeśli potrzebujesz kupić maszyna do cięcia na długość o średniej grubości

Zapraszamy do kontaktu z KINGREAL SLITTING – służymy Państwu pełną obsługą. Wybierając odpowiednią linię do cięcia poprzecznego o średnim rozmiarze, zwiększysz wydajność produkcji i obniżysz koszty, a tym samym zajmiesz korzystniejszą pozycję na konkurencyjnym rynku.

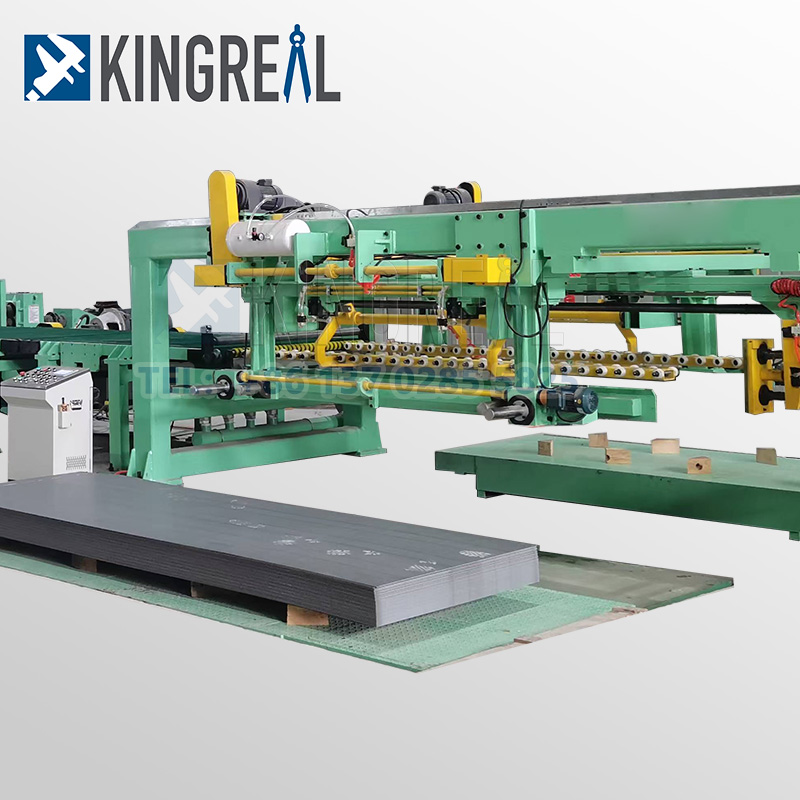

1. Trolley for medium duty cut to length machine

The decoiler is the first important link in the medium gauge cut to length line. Its main function is to unwind heavy metal coils and feed them into subsequent processing equipment. KINGREAL SLITTING decoiler is equipped with a feeding trolley that can automatically feed the coils into the decoiler, reducing the risk and labor intensity of workers manually handling heavy coils. This design not only improves work efficiency, but also ensures operational safety.

2. Straightening machine for medium duty cut to length machine

After the metal coil is uncoiled, it often warps or deforms to a certain extent. At this time, the role of the leveling machine is particularly important. The leveling machine restores the flatness of the metal sheet by applying appropriate pressure and stretching, ensuring the accuracy and quality of the subsequent shearing process. For customers who have extremely high requirements for the flatness of the sheet, KINGREAL SLITTING can equip them with two leveling machines to perform two leveling processes to ensure the final quality of the product.

3. Shearing machine for medium gauge cut to length line

The shearing machine is the core component of the medium gauge cut to length line, responsible for cutting the metal sheet into the specifications required by the customer. KINGREAL SLITTING provides a variety of shearing methods for customers to choose from, including flying shearing cut to length line (80 m/min), swing shearing cut to length line (80 m/min), rotary shearing cut to length line (80 m/min) and fixed shearing cut to length line(50 m/min). Different shearing methods are suitable for different production needs, and customers can choose according to actual conditions.

4. Stacking machine for medium gauge cut to length line

The metal sheets after cutting need to be stacked for subsequent handling and transportation. KINGREAL SLITTING is equipped with an automatic stacking table for the medium gauge cut to length machine, which can automatically stack the cut sheets and achieve efficient handling. In order to further improve production efficiency, KINGREAL SLITTING can also equip the medium gauge cut to length line with two stacking tables to ensure the continuous operation of the medium gauge cut to length machine.

Application of Medium Gauge Cut to Length Line

1. Production of flat sheet metal for roofing and cladding

In the construction industry, flat sheet metal is widely used in the production of roofing and cladding. Such sheets require good weather resistance and strength to ensure service life in various climatic conditions. With the medium gauge cut to length machine, manufacturers can quickly produce sheet metal that meets specifications according to project requirements.

2. Manufacture of precision automotive body panels

The automotive industry has increasingly high requirements for sheet metal, especially in the manufacture of body panels, where precision and surface quality are crucial. The medium suty cut to length line can efficiently produce precision sheets that meet various standards to meet the needs of automobile manufacturers.

3. Blank production in home appliance manufacturing

In the home appliance industry, sheet metal is often used to manufacture shells and internal structures. With the medium gauge cut to length machine, manufacturers can quickly cut out the required blanks for subsequent processing and assembly.

4. Support for custom-sized sheet metal for construction projects

As the demand for customization in the construction industry increases, the medium duty cut to length line provides a flexible solution for construction projects. Manufacturers can produce sheet metal of different sizes and shapes according to the specific needs of customers, greatly improving production flexibility.

Main Features of Medium Gauge Cut to Length Line

When choosing a medium gauge cut to length machine, the features of the medium duty cut to length line are also an important consideration. Here are some of the main features of KINGREAL SLITTING medium gauge cut to length machines:

|

1. Precision cutting for medium gauge cut to length line

In order to meet customers' demand for high-speed shearing, KINGREAL SLITTING has equipped the medium gauge cut to length machine with a flying shear system or a rotary shear system. These systems can effectively guarantee the length requirements of the plate and ensure the smooth progress of the production process, both in terms of production efficiency and cutting accuracy.

2. Leveling technology for medium duty cut to length line

Using a leveling machine to remove the warping of the coil and ensure the flatness of the plate is a major advantage of KINGREAL SLITTING medium duty cut to length machine. If the customer has higher requirements for the flatness of the plate, KINGREAL SLITTING can also provide two leveling stations to ensure the best flatness during the production process. |

|

|

3. Automated operation for medium gauge cut to length line

KINGREAL SLITTING has achieved automated operation by equipping the medium gauge cut to length machine with a PLC control panel. The operator only needs to enter the parameters on the control panel, and the medium gauge cut to length line can operate automatically, minimizing labor costs and improving production efficiency.

4. Material diversity for medium gauge cut to length machine

KINGREAL SLITTING medium gauge cut to length lines can handle a variety of materials, including steel, aluminum, and stainless steel. This material diversity allows customers to more flexibly choose the right materials to meet market demand when producing different products.

5. Stacking system for medium gauge cut to length machine

In order to improve production efficiency, KINGREAL SLITTING has equipped the medium duty cut to length line with an automatic stacking table that can automatically stack the plates after cutting. This design not only improves handling efficiency, but also reduces the need for manual intervention, further optimizing the production process. |

|

How to Choose Right Medium Gauge Cut to Length Line for Your Business?

Choosing the right medium gauge cut to length machine for your business is an important decision-making process. Here are some suggestions to help you make an informed choice:

1. Evaluate your needs

Before choosing a medium duty cut to length line, you first need to clarify the thickness range and length requirements of the metal coils you need to process. This will directly affect the type and configuration of the medium gauge cut to length machine you choose.

2. Evaluate the type of material

Make sure the selected medium gauge cut to length line can handle your specific material, such as stainless steel, aluminum, copper, etc. The physical properties of different materials will affect the cutting process, so you need to choose the right medium gauge cut to length machine.

3. Consider your production goals

Match the speed and capacity of the medium gauge cut to length line to your production requirements. If your production goals are high, you may need to choose a more efficient shearing method and medium gauge cut to length machine configuration to ensure the continuity and stability of production.

4. Budget planning

When choosing medium gauge cut to length line, you need to find a balance between initial cost and long-term savings. Although the initial investment of high-end medium gauge cut to length machine is larger, if it can significantly improve efficiency and reduce waste, it will ultimately bring greater economic benefits to the company.

5. Consult the manufacturer

Working with a reputable supplier is key to ensuring that you choose the right medium gauge cut to length line. By communicating with the manufacturer, you can get professional advice and customized solutions to meet your specific application needs.

If you have a need to purchase a medium gauge cut to length machine, please feel free to consult KINGREAL SLITTING, we will serve you wholeheartedly. By choosing the right medium gauge cut to length line, you will be able to improve production efficiency and reduce costs, thereby occupying a more advantageous position in the competitive market.

5. Skonsultuj się z producentem